Broiler Management and Disease Control Guide

Broiler Management and Disease Control Guide for Indian Poultry Farms (Practical Manual for Indian Poultry Farms)

Broiler farming looks simple from outside, but farmers who are actually on the field know that it is one of the most sensitive livestock businesses. Broilers grow very fast, margins are tight, and even small management mistakes can turn a profitable batch into a loss-making one. Most problems seen on broiler farms are not sudden; they build up silently due to poor planning, weak observation, and delayed correction.

In Indian conditions, broiler losses rarely happen because farmers do not work hard. They happen because management decisions are taken without understanding how the bird’s body responds to environment, feed, water, and stress. Disease is usually the final outcome, not the starting point. That is why broiler management and disease control should always be seen as one integrated system, not as two separate topics.

This guide is written for practical use. It is meant for farmers, supervisors, and poultry entrepreneurs who want to understand why things go wrong on broiler farms and how to prevent problems before medicines become necessary. Good broiler farming is not about using more products; it is about creating conditions where birds perform naturally close to their genetic potential.

Understanding the Broiler as a Biological System

A modern broiler is a fast-growing biological system. In just 5–6 weeks, the bird reaches market weight. This speed puts tremendous pressure on organs like the liver, kidney, heart, lungs, and digestive tract. Any imbalance during this short period reflects immediately in growth rate, feed conversion, immunity, and mortality.

Broilers do not get “used to” stress. Heat, cold, poor air quality, wet litter, or water problems affect them immediately. When stress continues, immunity drops and common pathogens such as E. coli, Clostridium, or respiratory organisms take advantage. Farmers often blame disease, but the root cause is usually management-related.

Another important point is that broilers cannot compensate later for mistakes made early. Poor brooding, delayed feeding, dehydration, or temperature mismanagement in the first week permanently affects performance. This is why experienced farmers say that the first 7 days decide the final result of the batch.

Successful broiler management means understanding this biological limitation and planning every stage accordingly.

Housing and Farm Planning – Foundation of Broiler Performance

Housing is not just about putting birds under a roof. It is about creating a controlled environment where birds can eat, drink, rest, and grow without unnecessary stress. In Indian conditions, housing design decides whether a farm will survive seasonal challenges like extreme heat, cold nights, dust storms, heavy rain, or humidity.

Site Selection and Orientation

The first mistake many farmers make is choosing a low-lying or poorly drained site. A broiler farm should always be built on a well-drained location with good natural air movement. Water logging around the shed increases humidity, fly problems, and disease pressure.

Orientation of the shed plays a major role in temperature control. An east–west orientation is preferred because it reduces direct sunlight exposure on sidewalls during the hottest part of the day. This small planning step reduces heat stress significantly in summer.

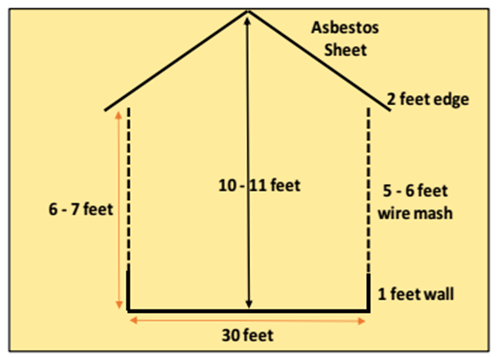

Shed Width, Height, and Ventilation

Ventilation is the backbone of broiler health. In open-sided houses, shed width should ideally be around 25 feet which is best and should not exceed 30 feet under any condition. Wider sheds restrict air movement, especially during hot and humid weather.

Roof height matters more than many farmers realize. The middle height of the shed should be around 9–11 feet, and side height around 6–7 feet. Adequate height allows hot air and gases like ammonia to move away from birds. Low roofs trap heat and moisture, leading to respiratory stress and poor growth.

Roof overhang of around 0.6 meters is important to prevent rainwater entry and direct sunlight. Roofing material should provide insulation and should not leak. In hot regions, additional roof insulation or thatch helps reduce inside temperature.

Open House Reality in India

In most parts of India, broiler farms are open-sided. Temperature control is done using curtains, brooders, heaters, fans, foggers, or sprinklers depending on the season. Curtains are not decoration; they are tools. Knowing when to open or close them is a skill that comes from observation.

In summer, cooling systems like fans and foggers help reduce heat load, but they must be used correctly. Excessive fogging without ventilation increases humidity and worsens stress. In water-scarce areas, simple methods like wet gunny cloth curtains on the windward side can also reduce temperature effectively.

A well-planned open house can perform very well if ventilation and seasonal management are handled properly.

Durability of Farm Structure – Often Ignored, Always Costly

Many farms are built using bamboo, wood, or weak materials to save initial cost. This often turns into a disaster during storms or strong winds. A damaged shed can wipe out the profit of an entire year in one event. Durability should never be compromised, especially in regions prone to dust storms, cyclones, or heavy rain.

A farm structure should be designed to survive local climatic challenges. Spending a little more at the construction stage saves repeated repair costs and production losses later.

Stocking Density and Space Management

Correct stocking density is one of the most critical but misunderstood aspects of broiler management. Overcrowding increases heat stress, reduces feed intake, worsens litter quality, and increases disease pressure. Understocking, on the other hand, increases production cost per bird.

In warmer climates like India, an average stocking density of around 30 kg live weight per square meter is closer to ideal. Practical field management often uses partitions to create pens of 600–700 birds, which helps in better observation and control.

A simple thumb rule many successful farmers follow is:

- First 10 days: 3 chicks per square foot

- Next 10 days: 2 chicks per square foot

- Third 10 days: 1 bird per square foot

- After 30 days: 1 bird per 1.2 square feet

Ignoring space requirements directly affects growth, uniformity, and mortality, especially during heat stress or disease outbreaks.

Equipment, Water, Feeding & Litter Management

(Where most broiler farms actually win or lose)

After housing and space planning, the next deciding factors in broiler performance are equipment placement, water availability, feeding method, and litter condition. These are daily management issues, not one-time decisions. Most diseases start showing symptoms here long before mortality begins.

Equipment Management – Access Matters More Than Quantity

Providing feeders and drinkers is not enough. Accessibility is what determines intake. A bird that cannot reach water or feed easily will never perform, no matter how good the ration or medicine is.

Water is the first and most critical nutrient for broilers. Without adequate water intake, feed consumption automatically drops, growth slows down, and immunity weakens. Many farmers try to fix this later with medicines, but the damage has already started.

In the first 7–10 days, chick drinkers are essential. Around 16–20 mini drinkers per 1000 chicks should be placed evenly so that chicks do not have to walk more than 8 feet to find water. As birds grow, these should be replaced with bell drinkers at the rate of one drinker per 70 birds.

Drinkers must always be adjusted to the correct height. The base of the drinker should be at the level of the bird’s back. If drinkers are too low, water spills and litter becomes wet. If they are too high, birds drink less, leading to dehydration and reduced feed intake.

Open vs Closed Watering Systems

Open systems like bell or cup drinkers are common because of lower initial cost. However, they come with problems—wet litter, poor water hygiene, contamination by feed and droppings, and higher labor requirement for cleaning. Maintaining water quality in open systems is difficult, especially in large farms.

Closed systems like nipple drinkers provide cleaner water and better litter condition. In high-flow nipple systems, 10–12 birds per nipple is recommended. In low-flow systems, around 10 birds per nipple works well. Nipples should be placed at a maximum distance of 35 cm to ensure easy access.

Birds should never struggle to find water. Any delay or difficulty directly affects growth and health.

Water Intake – A Direct Indicator of Farm Health

A simple rule of thumb is that water consumption should be around 1.6 to 2 times the feed intake by weight. This ratio changes with temperature, feed quality, and bird health, but it provides a good reference.

Temperature has a direct effect on intake:

- For every 1°C rise above 20°C, feed consumption drops by around 1.2%

- For the same increase, water consumption rises by around 6%

If water intake suddenly drops without an obvious reason, it is an early warning signal. Possible causes include poor water quality, blocked drinkers, disease onset, high ammonia levels, or temperature stress. Farmers who monitor water intake daily often catch problems much earlier than those who only look at mortality.

Water should be clean, cool, and free from biofilm. Even good medicines fail if water lines are dirty. Periodic flushing and sanitation of water lines is a basic but often ignored practice.

Feeding System – Early Feeding Sets the Direction

Feeding is not only about nutrition; it is also about timing and access. Broilers must start eating as early as possible. Delayed feeding reduces yolk sac absorption, weakens gut development, and increases early mortality.

In the first week, supplemental feeders such as trays or lids are essential. One tray per 100 chicks is a practical guideline. Some farmers use paper for the first 2–3 days, but paper increases wastage. A better approach is to provide feed on paper for 6–8 hours after chick arrival, then shift to chick trays.

Feed should be available immediately when chicks arrive. Running out of feed during the first few days is a serious mistake. Early feeding stimulates gut development, improves immunity, and supports uniform growth.

Feeder space is critical throughout the cycle. Insufficient feeder space leads to uneven growth and poor uniformity. For pan feeders, 50–70 adult birds per 33 cm pan is recommended. Feeders should be filled adequately but not overflowing to avoid wastage.

Very Imp. Point: It is of utmost importance that the additional feeders should not run empty as this will reduce yolk sac absorption. It means that feed should make available as soon as chicks arrived in the farm. Early feeding increases yolk utilization and reduces chances of yolk problems.

As birds grow, feeder height and feed level must be adjusted. In the beginning, feeders can be kept full. Later, maintaining feed at around two-thirds height reduces wastage while ensuring access.

Litter Management – The Hidden Profit Killer

Litter management rarely gets the attention it deserves, yet it has a direct impact on bird health, carcass quality, and final profit. Wet or compacted litter creates an ideal environment for bacteria, parasites, and ammonia production.

Poor litter condition leads to:

- Footpad dermatitis

- Breast blisters

- Higher ammonia levels

- Respiratory irritation

- Increased disease pressure

Litter should remain dry and friable. Raking should avoid in farms where ventilation in compromised. Many farmers underestimate ammonia because it is invisible. However, birds feel its effect long before humans do. If your eyes start burning inside the shed, birds have already been suffering for hours. Ammobond is very good substitute for raking and litter management which reduces ammonia and chances of respiratory diseases. Reusing litter increases disease risk and should be avoided unless proper treatment protocols are followed. If litter becomes damp, adding lime powder helps absorb moisture and control odor.

Good litter management improves bird comfort, reduces disease incidence, and directly supports better growth and feed efficiency.

Preparation of Poultry House Before Chick Arrival

Preparation before chick placement sets the tone for the entire batch. Cleaning and disinfection are not the same thing. Cleaning removes organic matter; disinfection kills pathogens. Skipping either step compromises biosecurity.

The shed, equipment, and surrounding area must be thoroughly cleaned and disinfected well before chicks arrive. Traditional fumigation using potassium permanganate and formalin (1:2 ratio) has been widely used, but it must be done carefully due to the violent chemical reaction involved. Proper dosage, container size, and safety precautions are essential.

Sanitrom can also be used to spray in farm before placing chicks.

Modern fogging systems reduce labor and time, but effectiveness depends on correct product selection and application method. Disinfection should be completed well in advance, allowing sufficient downtime before chick placement.

Brooding Management – The First Week Decides Everything

Brooding is the most sensitive phase of broiler farming. Chicks cannot regulate their body temperature until about 12–14 days of age. Any temperature error during this period affects survival and growth permanently.

Pre-heating the shed is essential. Floor temperature at chick placement is as important as air temperature. Temperature and humidity should be stabilized at least 24 hours before chick arrival.

Chicks should be placed immediately on arrival. Delays cause dehydration and stress. House lights should be dim during placement to calm chicks, then gradually increased.

A practical brooding setup for 300 chicks includes four 60-watt bulbs placed about 6 inches above the floor, a brooder guard of around 5 feet radius, along with four drinkers and four feed trays.

Chick behavior is the best thermometer. When temperature is correct, chicks are evenly distributed. If they crowd under the heat source, it is too cold. If they move away and pant, it is too hot.

Some farmers use jaggery solution with vitamins to reduce transportation stress. This can be helpful in small amounts, but excessive use causes early diarrhea and encourages harmful bacteria. Moderation is key.

Within 3 hours of feeding, at least 90% of chicks should have feed in their crop. This simple check tells you whether brooding and feeding are on track.

Temperature, Lighting, Growth Control & Disease Prevention Logic

(Where management decides disease outcome)

Temperature management is one of the most misunderstood areas of broiler farming. Many farmers rely only on thermometer readings, but birds respond to effective temperature, not just numbers. Effective temperature is influenced by air movement, humidity, stocking density, litter condition, and bird age. Ignoring any one of these factors leads to stress, poor feed intake, and disease outbreaks.

During the first week, chicks require a higher temperature because their thermoregulatory system is not developed. However, excessive heat is just as harmful as cold. Overheating causes dehydration, panting, and reduced early feed intake. Underheating leads to crowding, uneven growth, and higher early mortality. The correct approach is not to chase numbers but to observe chick behavior and adjust conditions accordingly.

As birds grow, temperature must be reduced gradually. Sudden drops or spikes cause stress. In colder weather, many farms close curtains too tightly at night to conserve heat. This often leads to oxygen depletion and carbon dioxide accumulation, increasing the risk of ascites and sudden death. Fresh air at night is essential, even in winter, though drafts must be avoided.

In hot weather, heat stress becomes the main enemy. Birds eat less, drink more, and divert energy towards cooling instead of growth. Proper ventilation, correct use of fans, and controlled fogging help reduce heat load. Excessive fogging without air exchange only increases humidity and worsens stress. Birds dying during the daytime are often victims of heat stress rather than infectious disease.

Lighting also plays a significant role in broiler performance. Continuous bright light forces birds to eat constantly, which may increase early growth but often leads to leg problems, metabolic stress, and higher late mortality. A balanced lighting program allows birds to rest, improves feed efficiency, and reduces sudden death syndrome.

Providing a dark period helps regulate hormonal balance and supports skeletal development. Many successful farms follow a program where light intensity and duration are adjusted gradually rather than kept constant. Birds given rest periods show better uniformity and stability.

Growth Control and Achieving Standard Body Weight

Modern broiler strains are genetically capable of rapid growth, but pushing birds too hard often backfires. Overfeeding in early life leads to weak skeletal structure, fatty liver, and heart stress. Controlled, uniform growth produces better final weight and lower mortality.

Body weight should be monitored weekly. Comparing actual body weight with standard breed targets helps identify problems early. However, average body weight alone is not enough. Uniformity is more important. A flock with slightly lower average weight but good uniformity performs better at market than a flock with high variation.

Poor uniformity usually indicates issues such as uneven access to feed or water, temperature variation within the shed, or early stress. These issues must be corrected immediately, as uniformity lost in early weeks is difficult to recover later.

Feed transitions also need careful handling. Abrupt changes from starter to grower or grower to finisher stress the gut and reduce feed intake. A gradual transition over 2–3 days helps maintain digestion and prevents growth setbacks.

Disease Prevention Through Management, Not Medicine

Most broiler diseases are opportunistic. Pathogens like E. coli, Clostridium, or respiratory bacteria are often present in the environment but cause disease only when birds are stressed or immunity is compromised. Therefore, disease prevention begins with management, not medication.

Poor ventilation leads to respiratory irritation and creates favorable conditions for CRD. Wet litter increases the risk of coccidiosis and bacterial infections. Nutritional imbalance or water contamination weakens immunity and gut health. When these factors combine, disease outbreaks occur.

Using medicines without correcting management faults provides only temporary relief. Birds may recover partially, but the underlying problem remains and reappears in the next batch. This is why farms that rely heavily on antibiotics often face recurring issues.

A preventive approach focuses on:

- Stable environment

- Clean water

- Balanced nutrition

- Stress reduction

- Early observation and timely correction

Medicines should support this system, not replace it.

Observation-Based Early Disease Detection

Experienced farmers detect problems before mortality begins. Birds communicate through behavior. Reduced movement, uneven distribution, altered droppings, changes in sound, or reduced feed and water intake are early warning signs.

For example, birds sitting quietly with ruffled feathers may indicate early infection or chilling. Panting and wing spreading suggest heat stress. Wet droppings with undigested feed indicate gut disturbance. Recognizing these signals allows timely intervention, often preventing major losses.

Daily walking through the shed, observing birds closely, and noting changes is one of the most effective disease control tools. Technology and products cannot replace attentive observation.

Role of Preventive Medicine Schedules

Preventive medicine schedules, such as a structured 42-day support plan, are designed to assist birds during predictable stress periods. They help support liver function, kidney health, gut stability, and immunity. However, they are not substitutes for proper management.

When used correctly, preventive schedules reduce the severity of problems and improve overall stability. When used blindly, they fail to deliver expected results. Understanding why a product is used at a certain age is more important than simply following a chart.

Records, Common Mistakes, Veterinary Support & Practical Closure

(Where good farms separate themselves from average farms)

Broiler farming is a short-cycle business. Because the cycle is only 35–42 days, farmers often underestimate the value of data and records. In reality, daily records are one of the strongest disease-prevention and profit-protection tools available on a broiler farm.

Importance of Record Keeping and Data Tracking

Problems in broiler farming rarely appear suddenly. They build up over time and give warning signals through changes in feed intake, water consumption, body weight gain, and mortality pattern. Farmers who record and review these parameters daily detect problems early and take corrective action before losses escalate.

The most important parameters to monitor are:

- Daily feed consumption

- Daily water consumption

- Water-to-feed ratio

- Mortality (daily and cumulative)

- Body weight at weekly intervals

- House temperature and humidity

A sudden drop in water intake is often the earliest sign of trouble, even before feed intake drops. Similarly, changes in feed intake patterns may indicate gut problems, temperature stress, or early disease.

Comparing current batch data with previous batches from the same farm is often more useful than comparing with textbook standards. Each farm develops its own performance baseline over time. Deviations from this baseline signal a problem.

Data should be recorded where it is collected, not later from memory. Simple charts, notebooks, or digital forms work equally well as long as recording is consistent.

Common Mistakes Farmers Make in Broiler Management

Despite best intentions, many broiler farms repeat the same mistakes batch after batch. Recognizing and correcting these mistakes is critical for long-term success.

One of the most common mistakes is reactive management—waiting for mortality to increase before taking action. By the time birds start dying, the problem has already caused performance loss.

Another major mistake is overdependence on medicines. Antibiotics are often used to cover up poor ventilation, wet litter, bad water quality, or feed problems. This approach gives temporary relief but creates long-term issues such as resistance, recurring outbreaks, and higher production costs.

Ignoring water quality is another frequent error. Farmers focus heavily on feed formulation but forget that birds consume almost twice as much water as feed. Dirty water lines, biofilm, or high mineral content reduce performance and increase disease risk.

Seasonal mismanagement is also common. Using winter-type strategies in summer or vice versa leads to avoidable losses. For example, tightly closing sheds at night in winter without adequate ventilation increases ascites risk, while inadequate cooling in summer leads to heat stress and sudden daytime mortality.

Poor observation is a silent but serious mistake. Walking through the shed without actually observing bird behavior, distribution, droppings, and sound results in missed early warning signs.

When to Consult a Veterinarian

While good management prevents most problems, certain situations require professional veterinary intervention. Relying only on online advice or standard schedules in these cases can worsen losses.

A qualified veterinarian should be consulted when:

- Mortality increases suddenly or sharply

- Birds show severe respiratory distress

- Blood appears in droppings

- Growth is severely depressed despite good feed and management

- A viral disease is suspected

- Vaccination failure is suspected

Veterinary consultation helps identify the root cause, prevents misuse of medicines, and reduces the risk of repeating the same problem in future batches.

Online consultation and preventive schedules are useful tools, but they do not replace on-ground diagnosis when serious problems arise.

Using Preventive Schedules and Manuals Correctly

This broiler management and disease manual is designed as a reference and guidance tool, not as a rigid rulebook. Every farm differs in terms of climate, housing, feed, water, and management skill. Blindly copying any schedule without understanding its purpose often leads to disappointment.

The correct approach is to understand the logic behind each recommendation and adapt it to farm-specific conditions. Preventive medicine schedules, management guidelines, and performance standards should support decision-making, not replace it.

Download the Complete Broiler Management & Disease Manual (PDF)

यह ब्रायलर मैनेजमेंट और डिजीज कंट्रोल गाइड भारतीय परिस्थितियों में ब्रायलर फार्मिंग को समझने और सही निर्णय लेने के लिए तैयार की गई है। ब्रायलर फार्मिंग में अधिकतर नुकसान बीमारी से नहीं, बल्कि खराब मैनेजमेंट, गलत तापमान, पानी की समस्या, गीला लिटर और देर से लिए गए निर्णयों के कारण होता है।

सही हाउस प्लानिंग, पर्याप्त वेंटिलेशन, उचित स्टॉकिंग डेंसिटी, साफ पानी, संतुलित फीडिंग और पहले सप्ताह की सही ब्रूडिंग ब्रायलर के पूरे जीवन चक्र को प्रभावित करती है। बीमारी अक्सर इन व्यवस्थाओं में कमी का संकेत होती है, न कि मूल समस्या।

रिकॉर्ड रखना, रोज़ाना बर्ड्स का निरीक्षण करना और पानी-फीड के पैटर्न को समझना शुरुआती चेतावनी देता है। दवाओं का उपयोग मैनेजमेंट के सहायक के रूप में होना चाहिए, न कि उसकी जगह।

यह गाइड एक सामान्य मार्गदर्शन है। अचानक अधिक मृत्यु, गंभीर बीमारी या वायरल संक्रमण के संदेह में नजदीकी पशु चिकित्सक से तुरंत संपर्क करना आवश्यक है। हर फार्म की स्थिति अलग होती है, इसलिए परिणाम मैनेजमेंट और पालन पर निर्भर करते हैं।